Precision Machining for the Aerospace Industry

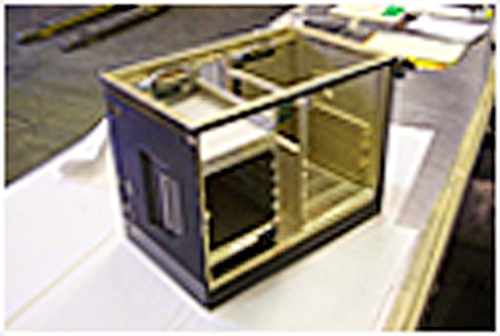

We mill a variety of components and enclosures of electronic or machine chassis for the aerospace industry. We have the capability to form parts up to 14′ and mill any complex detail to precision. Most of the tooling required to prototype or produce parts is built in-house to ensure longer part life. Value-added finishing services such as plating, powder coating, and anodizing are also offered.

Our specialty lies in 3 and 4-axis CNC milling of aluminum, steel, and stainless steel. Multiple vertical machining centers and power fed mills assist us in handling any prototype or low to high volume production run. Our Kitamura VMCs with 30-position tool changer options perform simultaneous, multiple milling operations at speeds of up to 20,000 rpm.

In addition to milling, we have 4-axis CNC turning centers that accommodate bed length of 4” by 12″. For mechanical assembly operations, we also offer EDM services. Every machined part undergoes FEA analysis prior to shipping. We employ GMP-compliant manufacturing practices specified by USFDA standards.

Equipment Used

| 1- Kitamura Mycenter 3 X IF Vertical Machining Center | 17.9" x 30" Travel 20,000 Rpm Spindle 30 Tools |

| 1- Kitamura Mycenter 1 – Vertical Machining Center | 13000 Rpm Spindle 14" x 16" Travel 20 Tools |

| 2- Kitamura Mycenter – 3 X I Vertical Machining Center | 15000 Rpm Spindle 17.9" x 30" Travel With Pallet Changer 30 Tools |

| 5- Fadal CNC Vertical Machining Center VMC 3016 | 10,000 Rpm Spindles 21 Tools 30" x 16" Travel |

| 1- Doall Automatic Horizontal Fixed Head Saw, Model# C916a | 11 Diameter Capacity With Hydraulic Feed |

| 1- Bridgeport Milling Machine | Digital Readout Power Feed |

| Other Equipment | 1- Burgmaster Multi-Spindle 1- Empire 23" x 36" Sandblaster 1- Walker Turner 1/2" Capacity 5- Black Granite Surface Plates |